Industry Expertise

KEV Series Electrically Heated Vaporizing Pressure-Reducing Regulator

Maximize uptime and minimize disruption with the Swagelok KEV Series Regulator

Design to Avoid Danger

Safe working conditions start with careful design considerations. Before you replace parts or put a completely new system in place, brush up on these best practices.

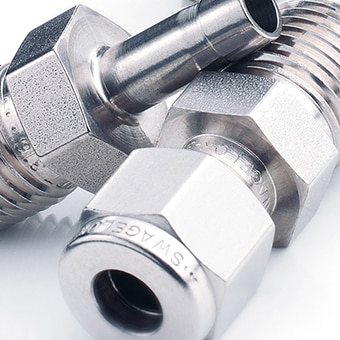

Driving Down Costs With Small Bore Tubing

The installed cost of a fluid system is just one aspect of its total expense. Proper planning and attention to detail can eliminate unexpected spending over time. Here are some suggestions for controlling the cost of installed systems, leakage , and corrosion.

Preventing Hose Failures

Hose failure can be costly, and can impair safety and efficiency. Learn how to minimize the impact on your operations.

Know Your Leaks

Where safety and operating costs are important, even one leak in a system is too many.

Maintenance Reminders

System maintenance should be anything but routine. Make it part of your overall system health and safety practices.

Proper Training

Worker safety must be the number one priority, and proper training is a key element in ensuring everyone makes it home safely and that your business is protected. But what does a first-class training program look like?

Training as a Quality Investment

Most fluid systems are complex, costly investments. Optimizing processes and personnel is key to making operations even more productive. Explore ideas for increasing your workforce’s skill levels and improving the reliability and accuracy of sample systems.

Troubleshoot Your Analyzer

Tony Waters, the leading expert in the design of sampling systems, tackles some of the most common questions he’s encountered.

Simplify Sampling Systems

Consider reducing the complexity of your sampling system where it is difficult to maintain an accurate result. Pre-engineered and assembled subsystems are a good start.

10 Tips to Improve Sampling Systems

Diagnose and eliminate issues to increase efficiency and save money.

Understanding and Measuring Time Delay

Time delay in sample systems is the most common cause of inappropriate results from process analyzers. Learn how to reduce it.

Calibrating the Analyzer

Calibration is an important process and an absolute requirement in analytical systems, but care must be taken to perform this process properly. Learn how to maximize the accuracy of your measurements.

10 Sampling System Mistakes Harming Your Operation

Don’t disrupt your operation or risk your reputation any longer.